The Bianchi X4 Diaries Part TWO

"Digging up old dogs has the potential to lead you into a vortex of unnecessary old sentiment."

Ever thought of restoring an old steel bike from scratch yourself? Bicycle frame painting and restoration, including chrome plating is a job best left to the experts. In case you think you'll have a crack at it yourself, here's a few tips for first time bicycle frame painters.

Last April when I took the Bianchi X4 out to legendary frame painter Joe Cosgrove, we struck a deal, Joe would paint the Bianchi X4 for me, but the arrangement came with more than I'd bargained for. We agreed that since Velo Aficionado is a bike blog about cycling culture, then it would help me if I learnt all I could about bicycle frame painting. While I've been working on the Bianchi X4, I've also researched and published an article on the history of bicycle frame painting. Talk about total immersion, history and practical application all in one.

For a catch up, here is part one of When The New Dog Digs Up The Old Dog.

Working together with Joe didn't mean that I would try my hand at frame painting, no, better to leave Joe to work his genius there. The idea was that I'd learn all about metal polishing, plating and frame finishing techniques, this meant a ton of elbow grease. You might begin to think I'd got the raw end of the deal, think a bit more, if you're into bikes and a guy like Joe allows you to work alongside him in his own space, that's a privilege.

Now after ten months, we've completed the chrome plating and the Bianchi X4 is ready for preliminary masking and prep work before receiving it's first base coats of paint. Go back to last April, we started with a quarter of a century old steel Bianchi frame which had been grit blasted and re-painted sometime in it's previous life. The worst result of the X4's interim paint job meant that the original chrome plating had been consigned to oblivion.

Our first job was to chemically strip the paint, no problems there. Next Joe gave me some lessons in metal polishing, lessons which were followed up by the disappointment of having to re-do hours of meticulous polishing work. Remember in part one of, When The New Dog Digs Up The Old Dog, the advice went something like this ..... digging up old dogs has the potential to lead you into a vortex of unnecessary old sentiment. This new episode left me wondering about the talents of new dogs and their wayward tendencies. Here's how it went. I'd spent a long afternoon polishing the X4 investment cast fork crown. Next, by the the time Joe got to me with his question I'd transformed the dull metal into a glistening mirror finish. Joe's question ….. "We'd better call the electro plating firm and check to see whether we need to have any trace of the original plating stripped, prior to polishing?" The answer I didn't want to hear came next. So it was off to the platers with the frame and forks, wait a few days and start all over again.

Take two, we picked up the X4 from the platers, it now looked like something a red-hatted Jacques Cousteau had salvaged from the wreck of an ancient Roman trireme. This time I determined to polish the fork crown back to a state befitting of it's heritage in the long line of revered Bianchi race-bikes. We were in luck, the process went without a hitch and the gleaming metal finish restored ready for plating.

Bianchi X4 Columbus SLX forks after all deposits of original chrome plater were removed

The real surprise came when I decided to tackle the chain stays. While removing the old plating the platers had only put half the length of the chain stays into the tank and completely missed the braise on for the front derailleur. Back in Joe's Fiat for another drive up the road, then it went from bad to worse. The plating company left the frame in the tank too long, or two times was too much! We got it back and inspected the damage, the full length of the chain stays were a pitted mess, hardly the stuff you'd create a polished mirror finish from. We had two options, replace the chain stays or fill the pitting with bronze brazing then polish away. Joe's advice was to fill the pitted surface and start from scratch. You might be wondering how we achieved a mirror finish from this. Check out the photo sequence, it's amazing what you can do with metal polishing.

First we started carefully with a file, removing the bronze back to a level surface. Next the process of polishing began with 80, 120, 800 and then 1,200 wet and dry paper. Finishing with buffing compound and soft polishing using cotton cloth buffing wheels. Coaxing the metal into a mirror finish from it's lumpy blackened bronze state seemed an impossibility at first. The result of many hours of hard graft rewarded us with a finish ready to receive veil coats of copper and nickel, followed by a generous deposit of chrome plating. Now the X4's shiny bits look as good as the day it was made.

For the next step we'll begin preparing the frame for paint and decals. The time when I get to ride the X4 still seems a distant vision, in the meantime finding the components for the build will be the fun part. Stay tuned later in the year for Part 3 of "When The New Dog Digs Up The Old Dog." Next up in bike restoration stories, and one year on we'll be talking to Matt Leasegang who has almost completed the build of his Milo TTT bike.

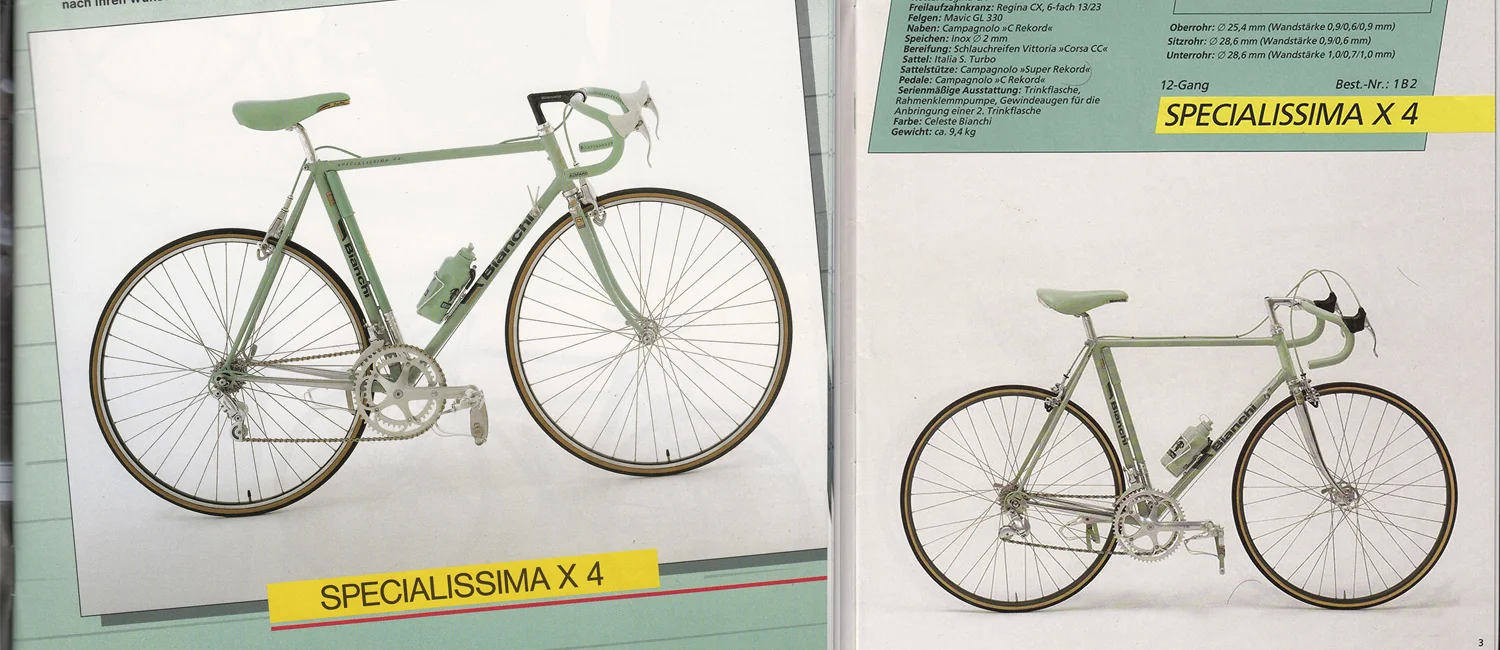

At the top of the image set is the Bianchi X4 team bike I'd raced on in 1987. That's what we've decided to aim for with the paint scheme.

The story of an almost new 1988 Bianchi x4, ridden only a few km's. Winner of Road Bike Of The Year at Pushies Galore 2015.